INTRODUCTION : In 2016, Enviro Infra Engineering Limited (EIEL) successfully commissioned a 21MLD Common Effluent Treatment Plant (CETP) in Panipat, Haryana.

Executed on a complete EPC (Engineering, Procurement, and Construction) basis- including detailed design, civil works, equipment supply, commissioning and ongoing operations and maintenance. This project underscores Enviro’s capability to deliver advanced, efficient and environmentally sustainable wastewater treatment solutions.

The Panipat CETP plays a pivotal role in treating industrial wastewater from multiple textile dyeing and processing units in the area, an area known for its high water consumption and complex e uent composition. By integrating advanced treatment processes and a robust operational framework, EIEL has enabled regulatory compliance reducing dependency on freshwater sources.

Founded in 2009 and structured as a public company since mid-2022, EIEL has developed deep expertise designing, constructing, operating and maintaining Water and Wastewater Treatment Plants, including STPs, and CETP, across India. The company handles all stages of project delivery, backed by an in-house engineering and civil team, ensuring seamless execution and quality control throughout the lifecycle of the project. EIEL’s business model is built on:

• Turnkey EPC delivery covering design, procurement, and construction of treatment facilities

• In-house civil engineering capabilities ensuring faster execution and tighter quality control

• Technology integration tailored to client specific effluent characteristics

• Long-term O&M contracts that guarantee sustained plant performance

Over the years, EIEL has executed projects for municipal authorities, industrial clusters and government bodies, consistently delivering solutions aligned with Zero Liquid Discharge (ZLD) objective and sustainability mandates.

Project Overview

• Location: Panipat, Haryana

• Capacity: 21 million litres per day (MLD)

• Type: Common E uent Treatment Plant (CETP)

• Execution Year: 2016

• Project Scope: End to end EPC execution, including design, civil construction, equipment procurement, and commissioning and long term operational maintenance.

The CETP serves several industrial units in the Panipat textile cluster, each contributing with high COD, BOD, TDS and colour load. The design of the plant incorporates multi-stage treatment to address these complex parameters, ensuring compliance with the discharge norms of the Haryana State Pollution Control Board (HSPCB).

Challenges

Panipat region faced mounting industrial e uent discharge from textile dyeing companies, which has a high concentration of dyes, salts and chemical auxiliaries. This necessitates a robust wastewater treatment solution. The requirement was for a facility that could not only treat but also enable reuse, minimizing environmental impact while meeting regulatory compliance.

Key challenges included:

• Significant variation in e uent characteristics across units, requiring a flexible treatment design

• Need for uninterrupted operations due to the continuous nature of industrial e uent generation

• Stringent deadlines tied to government funding schedules.

Solution & Implementation

EIEL’s approach was to deliver a robust, modular and adaptable CETP through its EPC capabilities:

• Design & Engineering: Multi stage treatment including equalization, primary clarification, biological treatment, tertiary polishing and advanced treatment (UF/RO) for water recovery. The design allowed for phased capacity expansion to accommodate future industrial growth.

• In house Civil Construction: Executed all civil works- including reactors, clarifiers, sludge handling facilities, and pump houses, using in house teams, enabling tighter cost control and adherence to timelines.

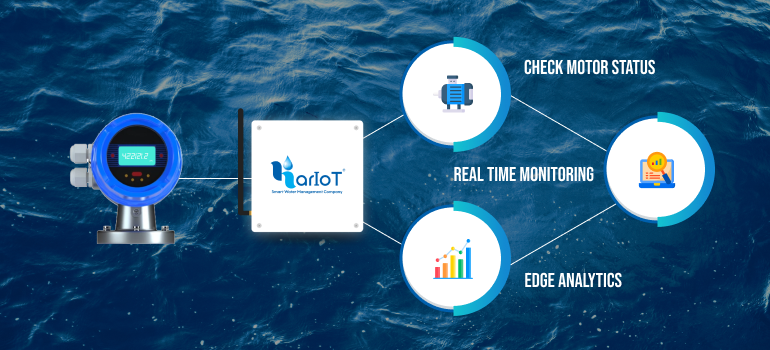

• Equipment & Technology: Procurement of high efficiency pumps, blowers, clarifiers, membrane systems, and sludge dewatering units from reputed OEMs. The plant was also equipped with SCADA-based automation for real time process monitoring and control.

• Commissioning and O&M: EIEL sta is well trained with standard operating procedures (SOPs), preventive maintenance schedules and performance audits to ensure smooth plant operation over long term.

Outcomes & Impact

• Environmental Stewardship: The CETP treats 21 MLD of complex industrial effluent daily, removing over 90% of COD and colour, and recovering up to 70% of water for reuse within the industrial cluster.

• Regulatory Compliance: Consistency meets HSPCB and CPCB discharge standards, avoiding penalties for member industries.

• Operational Reliability: The SCADA system allows for construction of treatment facilities predictive maintenance, reducing downtime by up to 20% compared to manual monitoring setups.

• Community & Economic Benefits: Reduces the burden on municipal water resources, enabling sustainable industrial activity without availability for local communities.

Conclusion & Key Learnings

• Holistic Execution: EIEL’s integrated approach covering site analysis, custom process design, construction, advanced technology integration and ongoing O&M ensures projects like Panipat deliver measurable environmental and operational results.

• Closing the Loop: The Panipat CETP showcases EIEL’s commitment to water reuse and resource recovery, turning industrial waste into a sustainable water source.

• Replicability: The success of this project provides a scalable model for other industrial cluster facing similar wastewater challenges, particularly in water-stressed regions in India